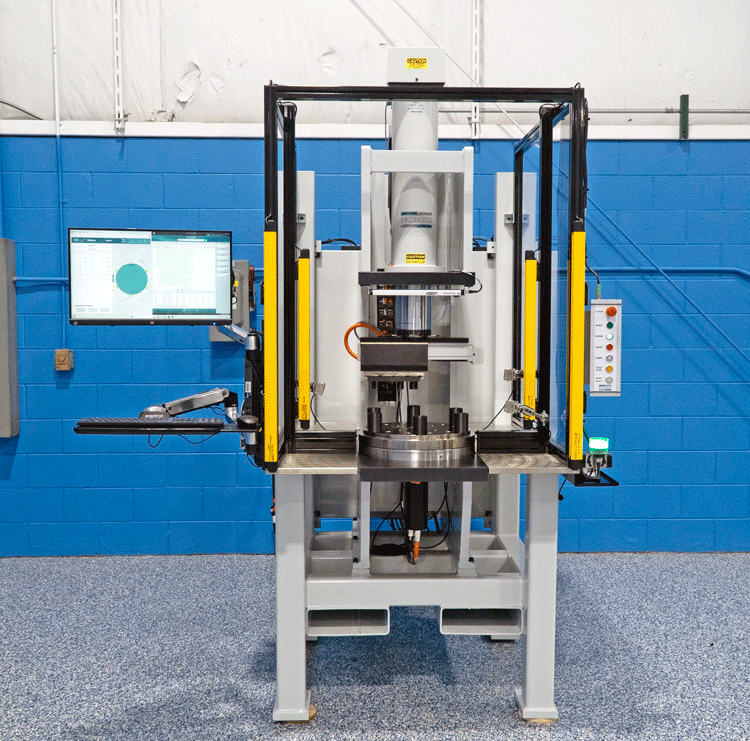

Promess continues to push the boundaries of what’s possible in automated manufacturing with a new engineered solution built specifically for semi-automated assembly processes. This flexible, high-performance Work Station is a complete machine-assisted system—designed to simplify complex assemblies, reduce operator error, and eliminate the need for a traditional PLC.

Precision and Power at the Core

At the heart of this system is the Promess Electric Press (EMAP), delivering up to 80kN of precision-controlled force. Like all Promess press systems, the EMAP is fully electric, offering programmable motion, real-time feedback, and closed-loop control for the most demanding applications.

Intelligent Tool Changing for High-Mix, Low-Volume Assembly

Attached to the press ram is a servo-driven slide tool changer, designed to handle multiple tooling attachments with ease. In this particular solution, four different customer-supplied tools are mounted to a tool pallet and used in sequence to progressively assemble a part. The tool changer allows the station to transition between pressing, staking, riveting, or other operations—making it an ideal solution for high-mix, low-volume environments.

Need even more flexibility? Multiple interchangeable tool pallets can be utilized for quick application changeovers without the need to reprogram or reconfigure the system.

Workflow Director: Your Smart Assembly Guide

To make complex operations simple for the operator, the Promess Workflow Director plays a central role. Compatible with barcode and RFID scanning, it instantly loads the correct application recipe into the Promess UltraPRO software. The operator simply scans the part, loads it, hits cycle start, and the system takes over—executing a highly repeatable and error-proof process.

Index Table Integration for Greater Automation

When paired with the Promess Index Table, the system becomes even more capable. This application features a 6-point indexing table equipped with safety light curtains and laser part presence sensors for safe, automated part transfer and process validation.

Thanks to Promess software integration, the index table can be configured with anywhere from 2 to 8 index points—or more, depending on application needs. Each part is tracked through the station with pass/fail identification, ensuring every unit meets quality standards before leaving the station.

The Complete Package

By combining the EMAP, Index Table, tool changer, and workflow director, Promess delivers an engineered workstation with unmatched flexibility, precision, and control. Whether you’re assembling a single part type or managing a variety of low-volume applications, this semi-automated solution gives you the tools to scale, adapt, and succeed.