TorquePRO | Torque System

TorquePRO

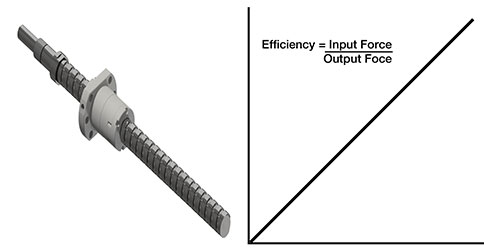

The Promess TorquePRO system is a fully electric, programmable, rotational actuator. Built to control torque and position in production and test environments.

The TorquePRO is the best solution for accurate and repeatable torque for manufacturing and test applications from 1 Nm and below, to over 15,000 Nm.

Control

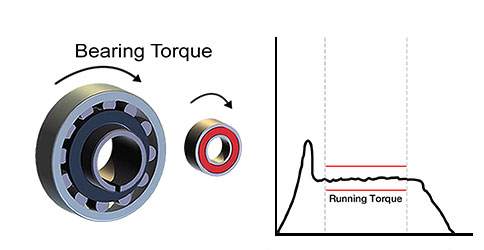

- Highly Accurate Motion Control

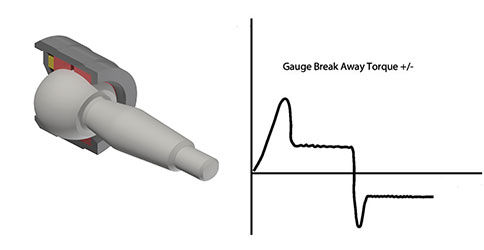

- Real time control and monitoring of torque and angle

- Control to a Torque, Position, or any number of other inputs

Monitor

- Verify every process or test meets its requirements

- Manufacture with no fault forward

- Never ship a bad part from your facility again

Robust

- Built-in mechanical overload protection

- Hold the rated load of the system indefinitely

- Sleek, compact design allows for easy integration or retrofit

Features and Capabilities

- Move to an angle

- Move to a torque

- Moves to multiple positions

- Hold to a constant torque

- Data acquisition and analysis

- Base mounts / face mount options

- Smooth running servo technology

- Easy integration

- Compact Design

Do you have an application?

Talk to one of our expert engineers and learn more about the Promess TorquePRO.

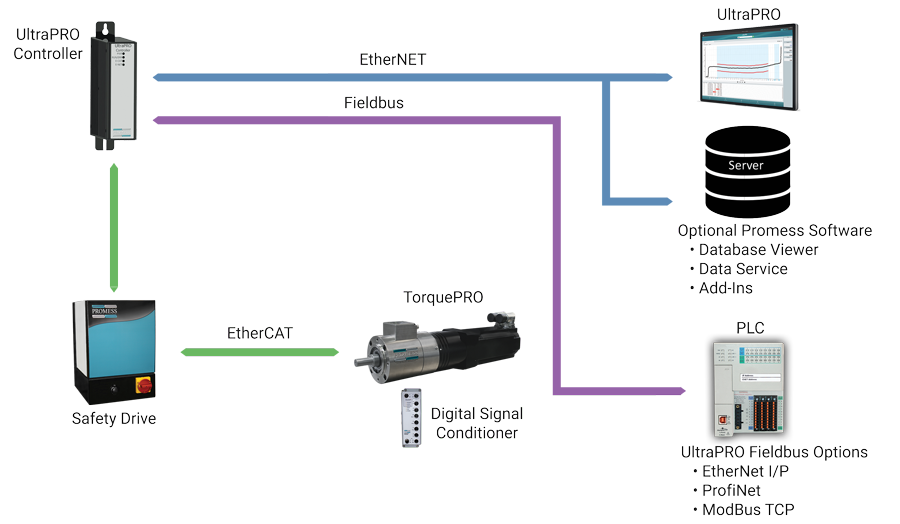

System Powered By Promess Software

Promess powerful system software solution offers custom commands, flexible configurations, and adjustable features to address your specific needs.

Features of Promess Software

- Easy to Use

- Traceability

- Data History

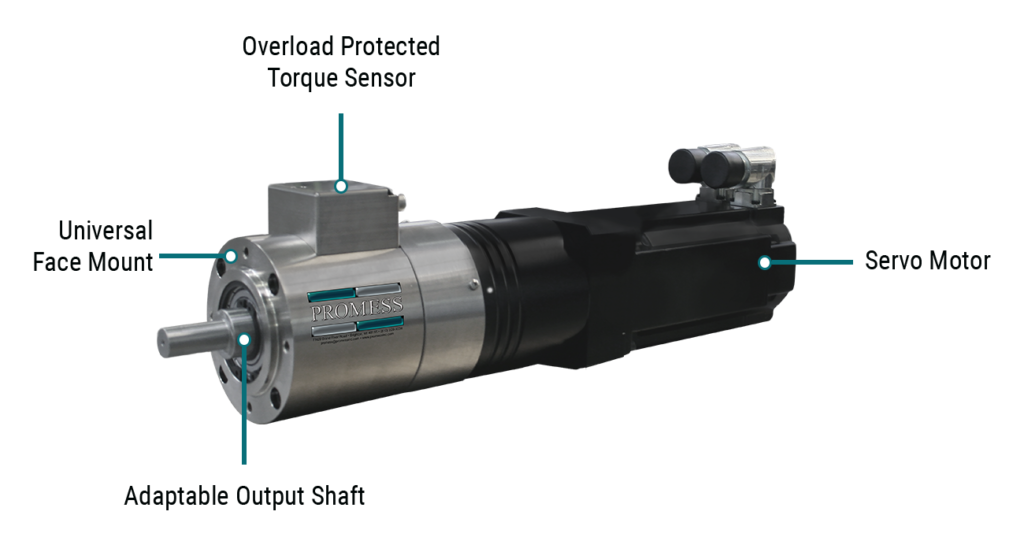

TorquePRO Mechanics

Complete System

What’s Included

- Integrated Torque Spindle Package

- Integrated Torque Transducer

- Servo Motor

- Plug & Play Design

- Compact

- Safety Drive Enclosure (SDE)

- Promess UltraPRO Controller

- Digital Signal Conditioner

- Cables

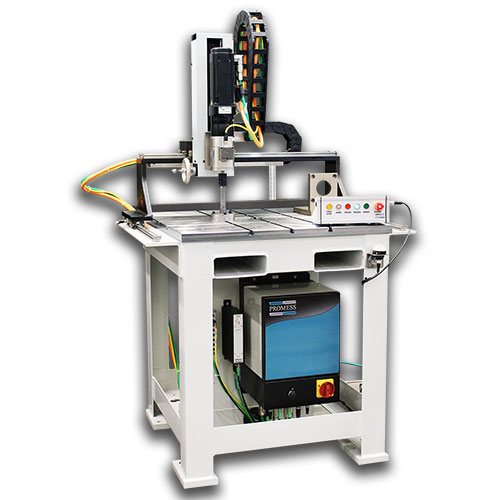

Looking for a More Tailored Solution?

Looking for a plug and play systems that allows you to be up and running same day as delivery? Learn more about our Work Stations.

TorquePRO Sizing

| Torque Capacity (Nm) | Torque Capacity (lb-in) | Max Speed (RPM) |

|---|---|---|

| 5 | 44 | 250 |

| 20 | 177 | 250 |

| 50 | 442 | 250 |

| 100 | 885 | 250 |

| 200 | 1,770 | 250 |

| 500 | 4,425 | 100 |

| 1,000 | 8,851 | 75 |

| 2,500 | 22,127 | 20 |

| 5,000 | 44,254 | 10 |

| 10,000 | 88,507 | 4 |

Other sizes available upon request, email [email protected].

Drawings available upon request, email [email protected].

Prove Out Your Process

The PDC is available to you for help verifying your process at no cost to you. Bring in or send in your parts and work with an engineer to find the technology best suited for your application.