Sensing and Motion Control Systems for Medical and Life Sciences Industry

Press and Torque in Life Sciences Assembly and Test

Promess offers scalable, in-process sensing and motion control systems engineered for the medical and life sciences industry. From early-stage development to full-scale production, our turnkey electric solutions offer the precision, control, and traceability needed to meet the standards of the medical industry. With programmable force and position control, real-time data analysis, and seamless integration of external sensors, Promess helps ensure every part meets exacting specifications—repeatably and reliably.

Precision Press and Torque Systems

Promess systems streamlines setup, reduces cycle times, and provide real-time data for traceability and continuous process optimization. Built to accommodate a wide range of component profiles, Promess systems programmability accelerate setup and part changeover while maintaining precision.

Fully Electric, Complete Solutions

Promess systems are a clean, precise alternative to hydraulic, pneumatic, or manual equipment. Available as standalone units or fully integrated plug-and-play solutions, we take full responsibility for key components—including the system base, press mechanics, control software, and integrated safety features.

Benefits of Electric, Data Driven Assembly

Precise Control

Monitor and control force, torque, and position with extreme resolution

Pass/Fail Monitoring

Instantly pass / fail every cycle using integrated software

Data & Traceability

Data acquisition and storage, full part history and display of graphs

Clean & Quiet Operation

Electric systems support cleanroom use, no fluid contamination

Low Force Capabilities

Can be scaled to very light loads for even the most sensitive and precise applications

Easy to Program

Intuitive software with job storage, recipe management, and remote access

Medical Processes

Promess systems are designed to perform and validate a wide range of processes commonly required in medical device manufacturing:

✔ Crimping: Controlled force for lead wires, catheters, and flexible tubing

✔ Joining & Press Fitting: High-precision press fits with real-time feedback

✔ Staking: Thermal or mechanical staking with precise position monitoring

✔ Inserting: Repeatable insertion of delicate parts with minimal variation

✔ Compression Testing: Functional validation of springs, valves, and seals

✔ Torque-to-Turn Testing: Ensure correct assembly and functional resistance

All processes are monitored and logged, with configurable pass/fail limits and visual graphs for process review.

Medical Manufacturing Applications

Applications

✔ Syringes & Single-Use Injectors Assembly

✔ Catheter and Tubing Joining

✔ Implantable Component Assembly

✔ Surgical Tool & Instrument Testing

✔ Hearing Aid & Wearable Device Assembly

✔ Batteries Assembly

✔ Powdered or Material Compacting

✔ Wire testing

Case Studies

Case Study: Battery Assembly

Medical Crimping Application

Vascular Closure Device

In-Process Motion Control Solutions

H-Series Press

The Promess Electro-Mechanical Assembly Press (EMAP) is a fully electric, programmable motion controlled ball screw press with integrated motion control.

Rotational Electro-Mechanical Assembly Press

The REMAP provides fully programmable, precise and independent control of both linear and rotational motion into a single unit.

Benchtop Press

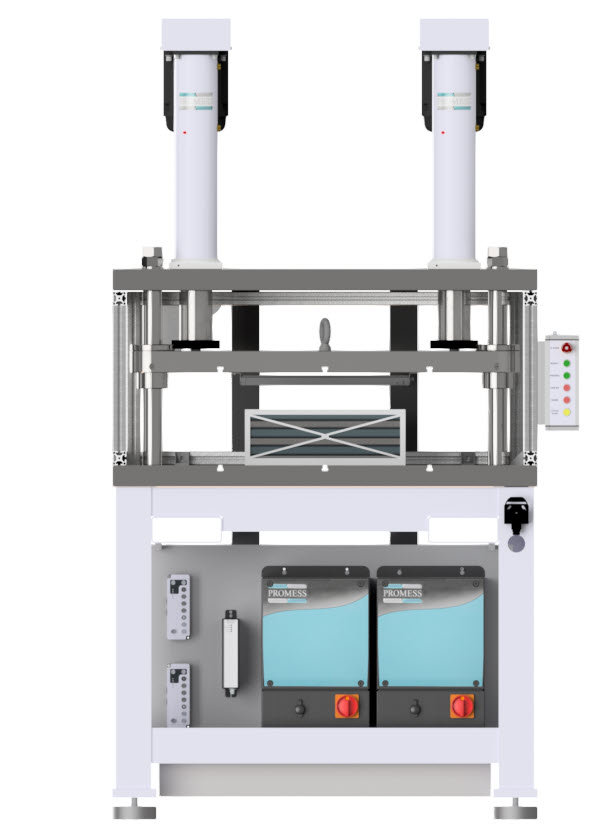

Work Stations

The Promess Benchtop Press Station is a fully electric stand-alone unit with an integrated Promess Electro-Mechanical Assembly Press, REMAP or TorquePRO.

TorquePRO Systems

The Promess TorquePRO system is a fully electric, programmable, rotational actuator. Built to control torque and position in production and test environments.

Ready to improve your medical assembly or test process?

Discuss your application with a Promess Assembly Experts and find the right solution for your application.