CASE STUDIES

Engineering Solutions for Manufacturing Challenges

At Promess, we specialize in delivering precision engineering solutions to overcome manufacturing challenges. As a leader in intelligent assembly and test systems, we provide manufacturers across industries with advanced technology that ensures accuracy, repeatability and reliability.

Case Studies

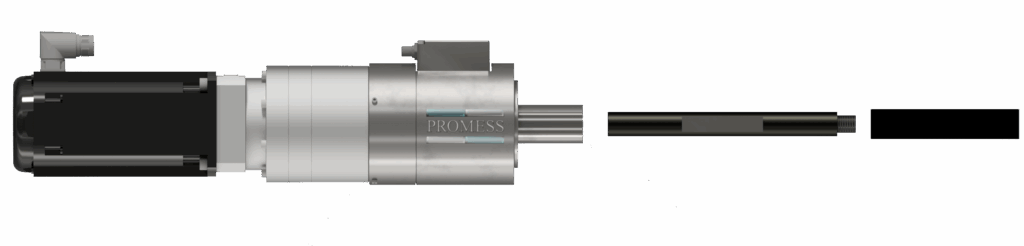

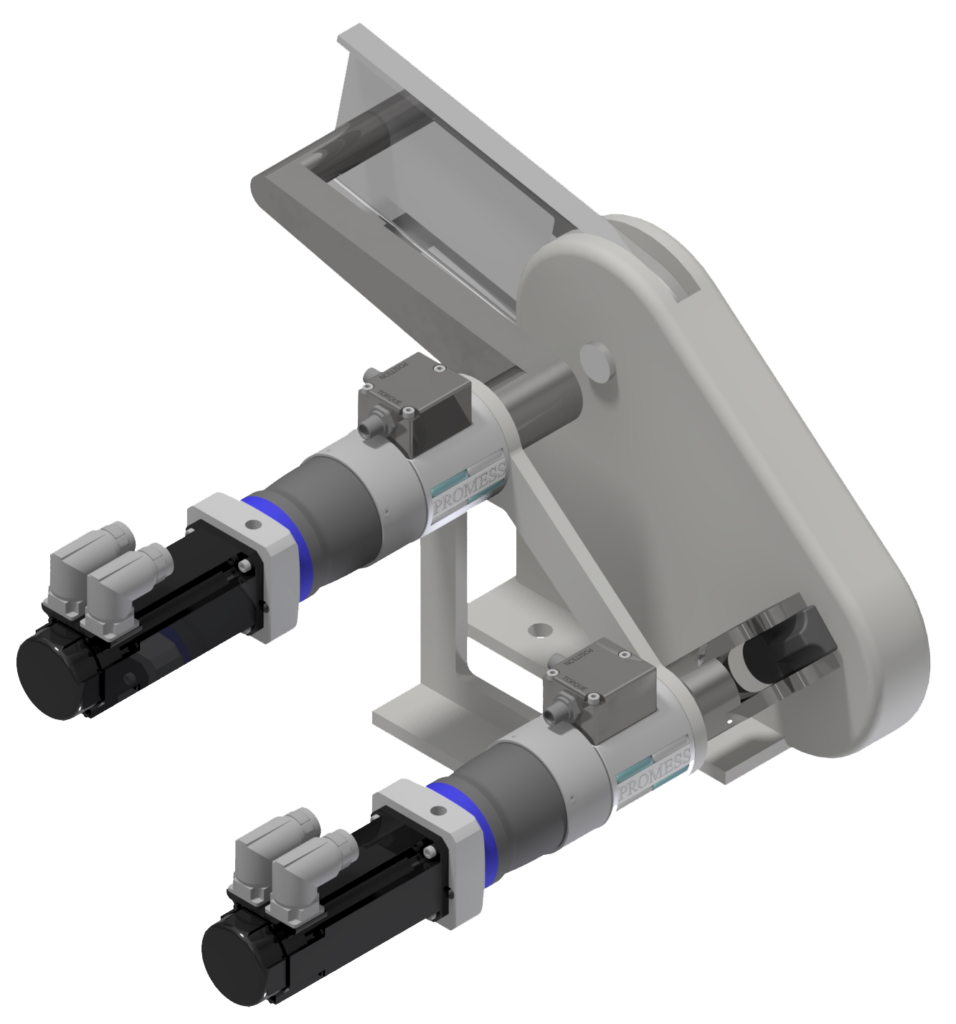

Gun Barrel Application

The customer faced a highly manual and operator-dependent process for mounting the rifle barrel to the receiver assembly …

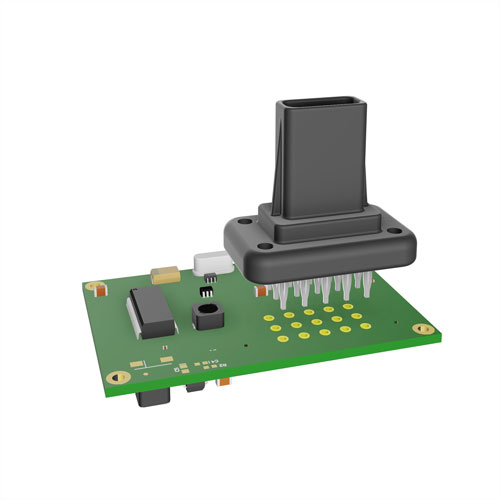

Circuit Board Assembly

Reducing defects and energy consumption in circuit board assembly by utilizing Promess Compliant Pin Press Assembly A leading …

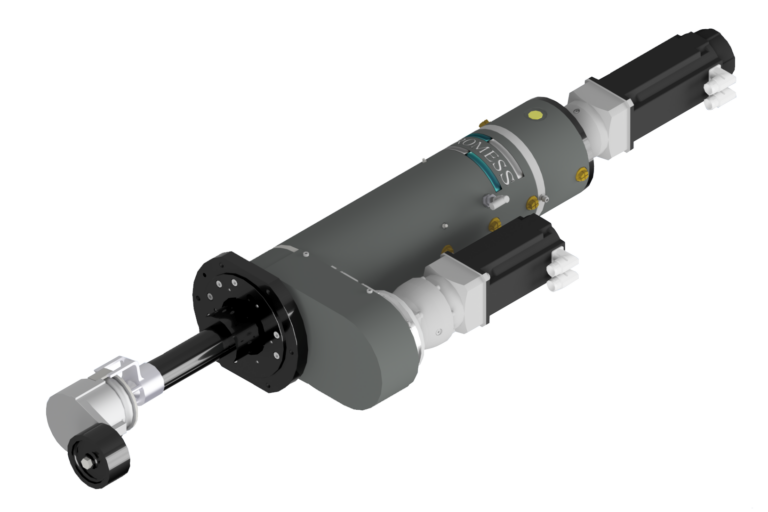

Assembling Automotive Belt Tensioners

Manufacturing automotive belt tensioners requires a highly coordinated assembly system that can precisely control both linear and rotational …

Desk Chair Bushing Testing

In the manufacturing of ergonomic desk chairs, one of the most critical components is the Torsion Bushing. This …

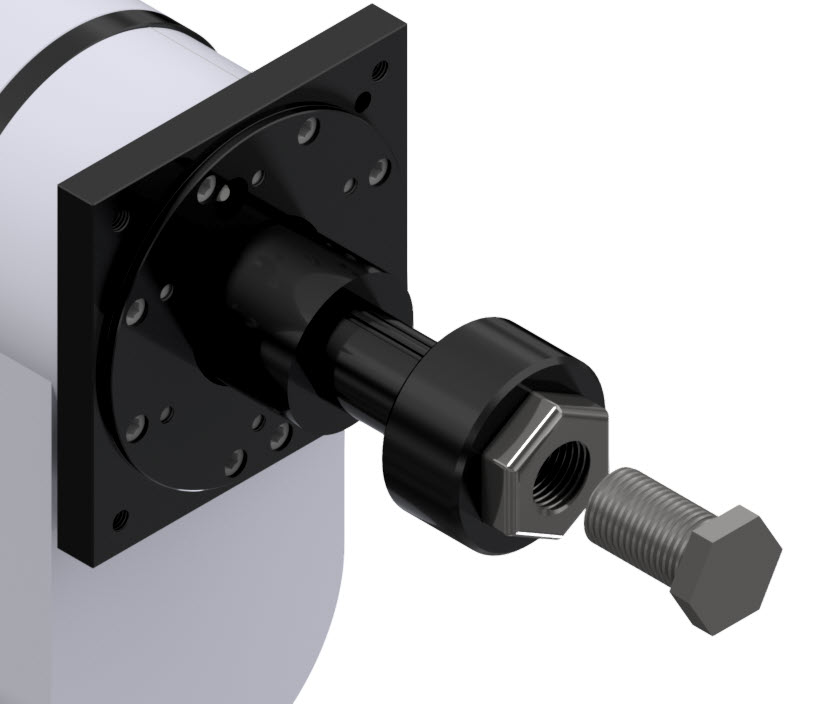

Cross Thread Prevention

A manufacturer faced significant quality issues when assembling two sub-assemblies that needed to be threaded together and torqued …

Seat Recliner Mechanism Testing

In the automotive industry, ensuring the safety and reliability of every component is crucial. One of the most …

Precise Torque Test in Brass Fitting Insertion

In the world of manufacturing, even the smallest component can cause significant headaches when quality issues arise. This …

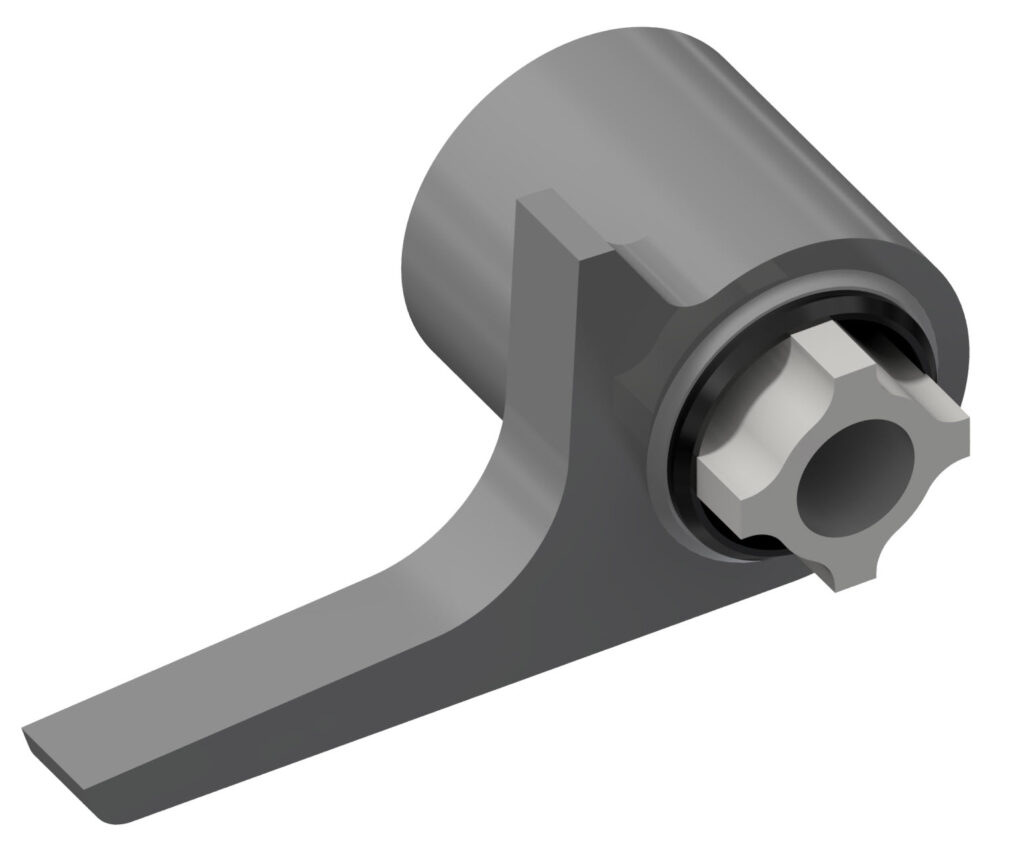

Assembly Universal Joints | Staking Application

In the world of automotive manufacturing, precision and reliability are critical. Universal joints, which connect the driveshaft to …

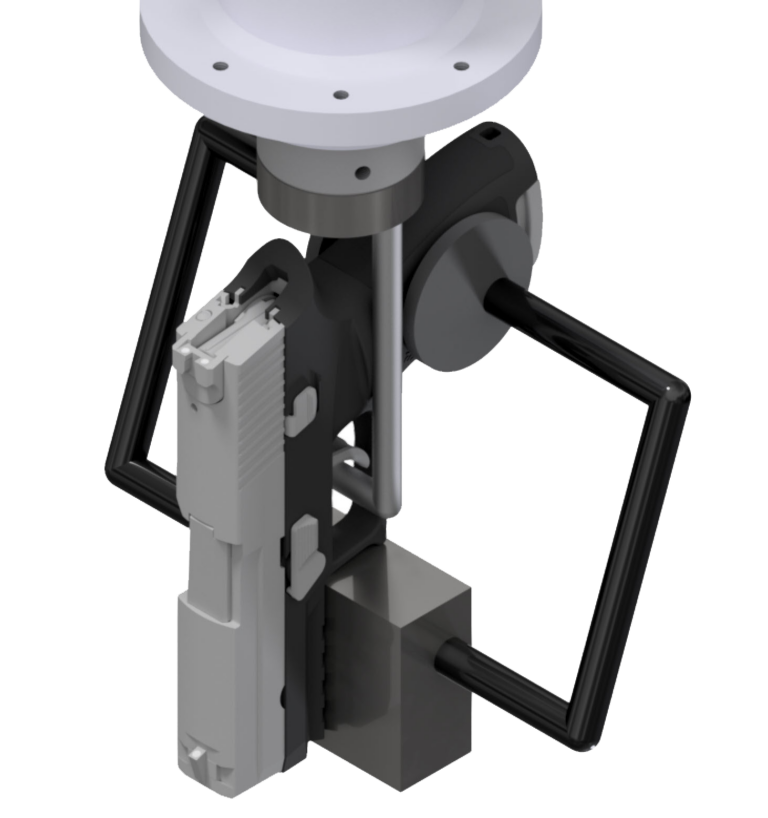

Trigger Pull Test Handgun Manufacturing

A manufacturer of handguns for the US Military sought a solution to verify that each firearm component met …

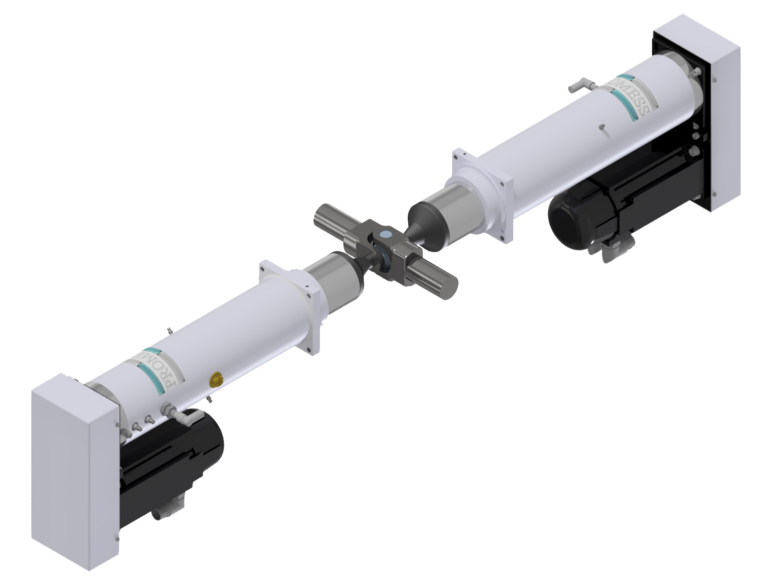

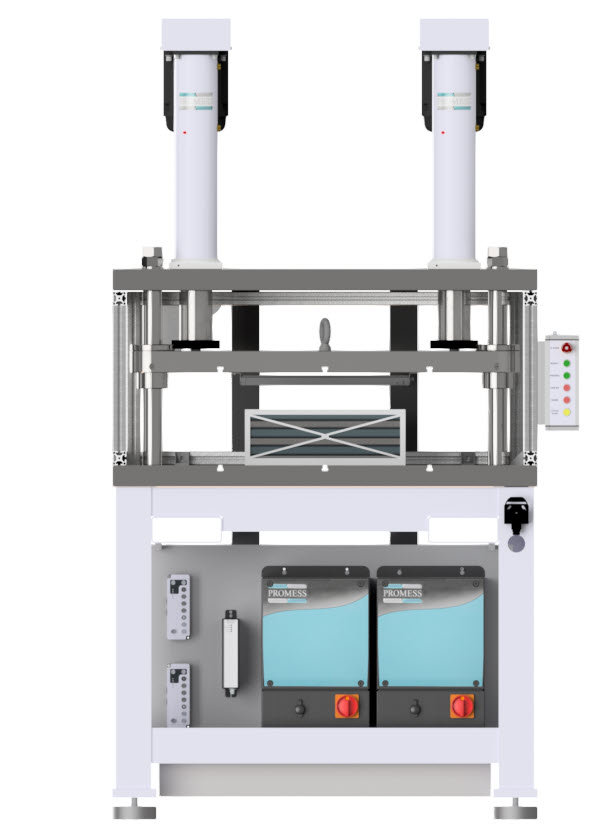

Composite Compression

The most common assembly process for composite parts is compression molding. Material is inserted between coordinated metal dies …

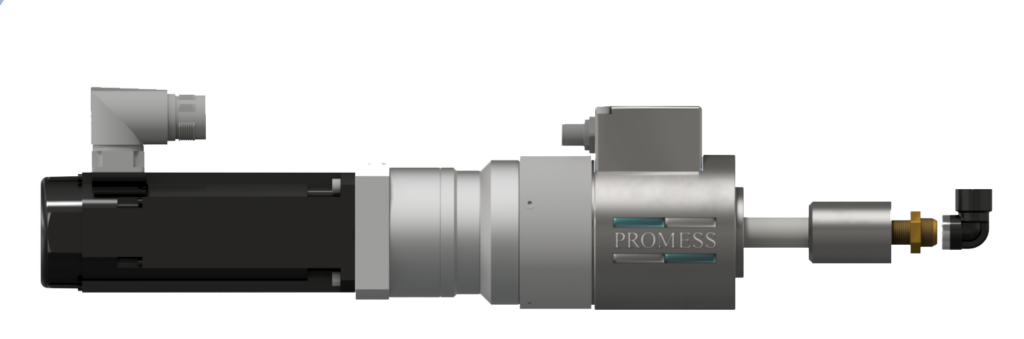

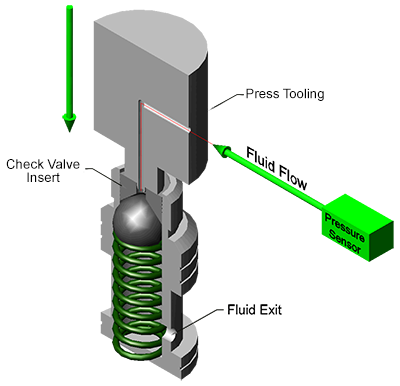

Hydraulic Pressure Relief Valve is Assembled and Tested Via EMAP

Valve manufacturers today are able to inspect parts during assembly rather than after to produce near-perfect fluid pressure …

Case Study: Battery Assembly

Customer was looking for a turnkey assembly cells that had flexibility, data storage and management, but more importantly, …

Do You Have an Application?

Talk to one of our expert engineers or learn more about proving your

application in our Process Development Center.