Functional gear assembly testing consists of a series of tests that simulate the function of a product to determine whether that assembly will function as it should, once used in the real world. Regarding gears especially, Promess’ methods for function testing have led to gear assemblies of exacting standards and previously unheard-of reliability and performance. If a gear mesh is too tight or too loose, Promess’ Functional Gear Assembly Testing will sense deviations from acceptable behavior in gear performance by monitoring, gauging and visualizing data obtained during the assembly process and subsequent cycling.

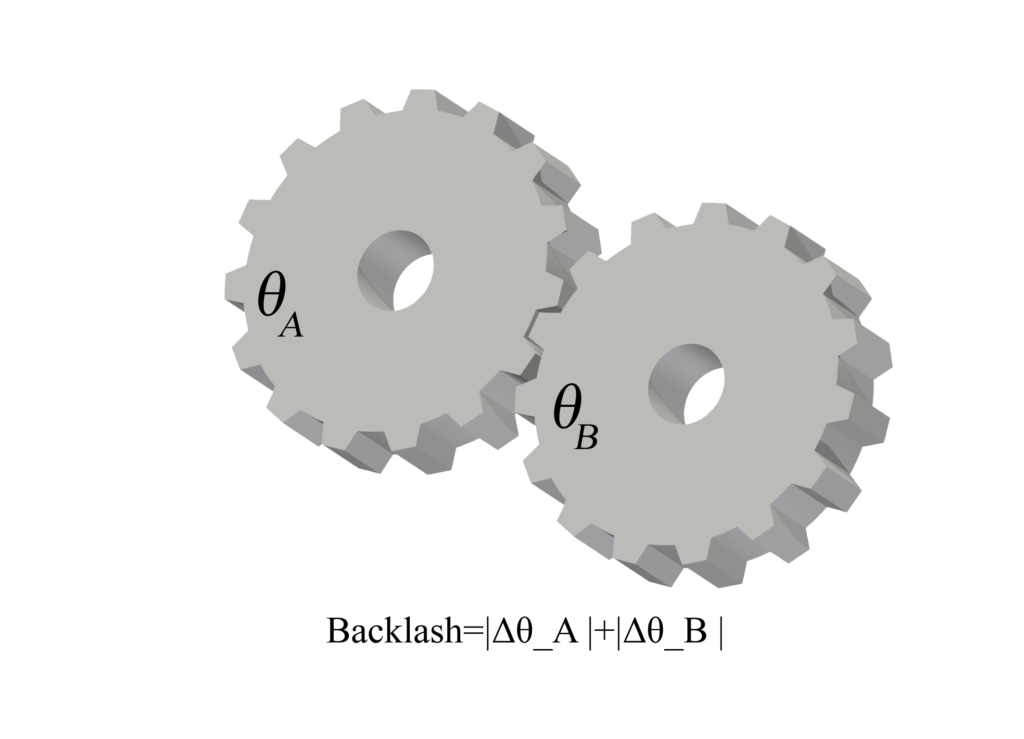

Characteristics such as the amount of torque required to rotate the gears, and the amount of backlash (or “play”) in the gear system are directly related to efficiency and undesirable noise. Additionally, gear efficiency, or the ratio of torque required to drive the input gear against a resistive torque being applied to the output or final driven gear is a great indicator of the overall energy effectiveness of the system and if a gearset is found to lack acceptable efficiency, that is also an indicator that there may be additional problems which not only affect the quality of what is being tested and produced, but may also shorten the life of the gearset itself.

The best systems for gear assembly not only put the gears together as needed but also verify the quality of the gearsets and back up those findings with data.