In today’s world of manufacturing, with higher-than-ever levels of competition and increasingly sophisticated and demanding customers, it’s not enough to just assume your processes are working as they should, nor can you assume your quality is as it should be – as the customer demands and expects just because there are no obvious, surface-level flaws.

The best way to ensure each and every product or component you produce “passes” or “fails” whatever standards you have determined most appropriate, is with in-process monitoring and gaging, an inherent feature in every Promess System for force/torque applications.

PROMESS IN MANUFACTURING

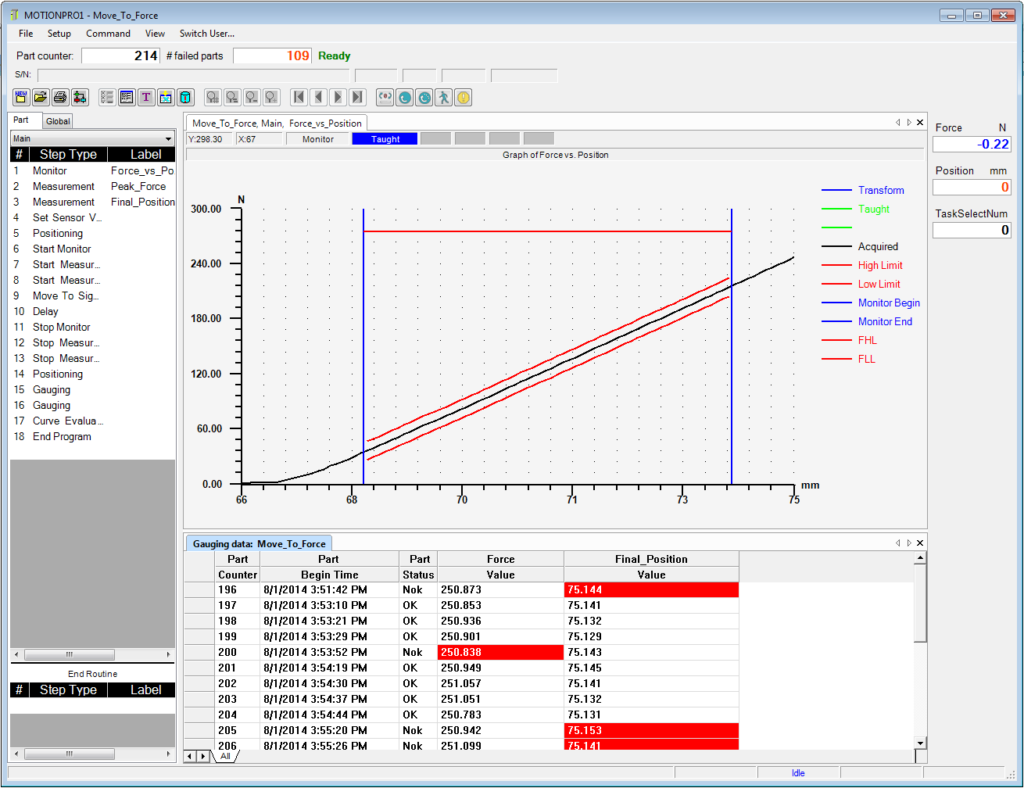

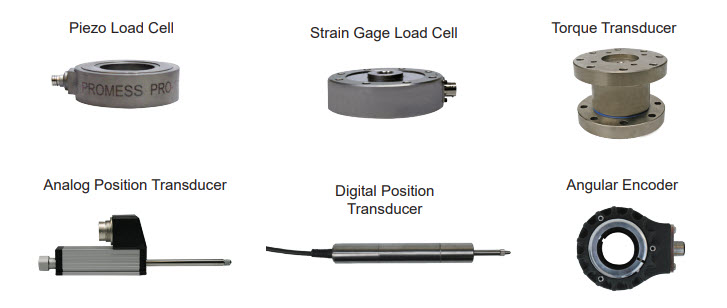

Promess started as a sensing company with the mission of giving manufacturers a sense of feel that gave them real-time insight regarding just what was occurring in their manufacturing processes, AS IT WAS OCCURRING. Integrated sensors including load cells, precision encoders, and additional external transducers where necessary along with powerful and easy-to-use monitoring and gaging software, allowing you to create a “signature”, or graph of relevant data, for each part, every time the process is executed. This signature is then, almost instantaneously, compared to the ideal, +/- the tolerances you have deemed acceptable, to return a pass or fail status before it even leaves the station.

PROMESS MISSION

Promess’ software not only gives you knowledge re: the pass/fail status of every part, it also gives you full control of how to respond.

Do you want to learn how Promess can help you tell if your part passed or failed? Contact Us to learn how!