PLC’s (Programmable logic controller) have existed in high tech manufacturing environments for decades.

They are a proven technology that has greatly improved the manufacturing process. The PLC provides greater control, easier troubleshooting, and the quick flexibility that keeps you “up and running.” Engineers and technicians alike have marveled at the technical possibilities of the PLC. As well as at the true beauty and simplicity of a well-designed PLC program.

Introduction

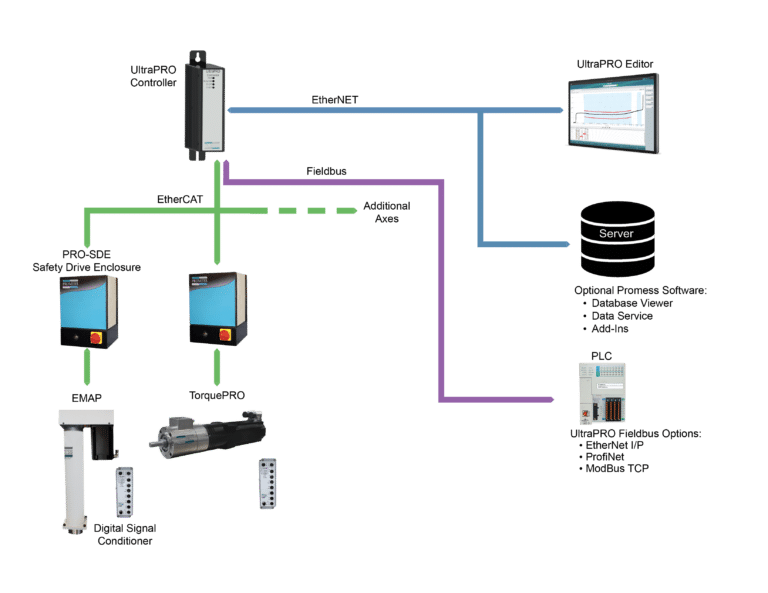

While PLC’s have greatly improved industrial production, they can make things a bit more complicated too. Especially in instances where the PLC is used to control and monitor multiple required processes to ensure quality assembly. All of which are necessary to ensure that quality assemblies are produced. Promess greatly simplifies your PLC program. Our systems contribute to producing the highest quality products. We provide you with data that verifies your process and individual product quality.

Assembly Process

When the part is loaded and the operator is ready to cycle the machine, the PLC only needs to initiate the cycle. Upon receiving that signal, the Promess System takes over the more complicated aspects of the process: pressing to a position or force, rotating to a position or torque, or otherwise processing the components to whatever other measurable aspect you need. They system completes monitoring & gaging work and collects the data you need to retain. Next the Promess sends an OK (or NOK if that is the case) signal back to the PLC to allow the next step in your process to commence.

Benefits of Promess System

Promess allows you to keep your PLC programming simple, letting the PLC to do what it does best. While the Promess System handles the more complex (and often more daunting programming-wise) tasks. Tasks such data collection and part evaluation. Resulting in a well-assembled components & final products, and data for verification & validation. While preserving a clean and intuitive PLC program that doesn’t have to get bogged down with countless sensors and inputs to ensure the highest quality, every time.

The Promess System with its uniquely designed and customizable software handles 100% of the critical aspects of the process. Not only do you get the best possible assembly to suit your and your customers’ needs. Promess provides 24/7/365 support, as close as your nearest telephone or internet connection, should any issue arise.

Promess provides you with solutions that are as complex as you need them to be, while still maintaining the beautiful simplicity that keep your operations running smoothly & effectively. Generating & maintaining the customer satisfaction that is sure to keep you prosperous long into the future!