REMAP | Rotational Electro-Mechanical Assembly Press

REMAP

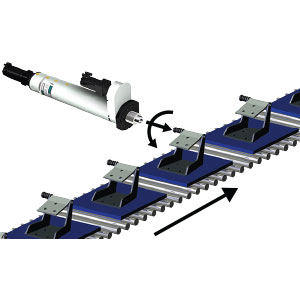

The REMAP provides fully programmable, precise and independent control of both linear and rotational motion into a single unit.

The REMAP is compact and easy to integrate into both new and existing systems. Unlike traditional linear / rotational systems involving complex designs and controls, the Promess REMAP comes in one complete, ready to run package.

Controllability

- Integrated force and torque sensors for controlling and monitoring the force and torque signals

- Independent control of both linear and rotational motion into a single unit

Repeatability

- Clone your assembly

- Duplicate, precisely for all production

- Fault condition if component is outside parameters for some reason

System

- Compact

- Easy to integrate into new or existing systems

- Complete, ready to run package

Features

Capabilities

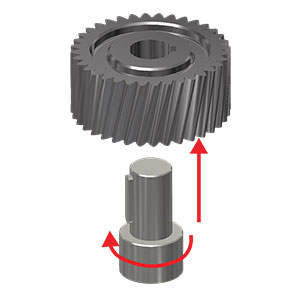

- Press to a Position

- Press to a Force

- Turn to an Angle

- Turn to a Torque

Programmable

- Position

- Velocity

- Acceleration

- Relative & Absolute Limits

- Angle

- Angular Acceleration

- Angular Velocity

Independently Controlled Motion

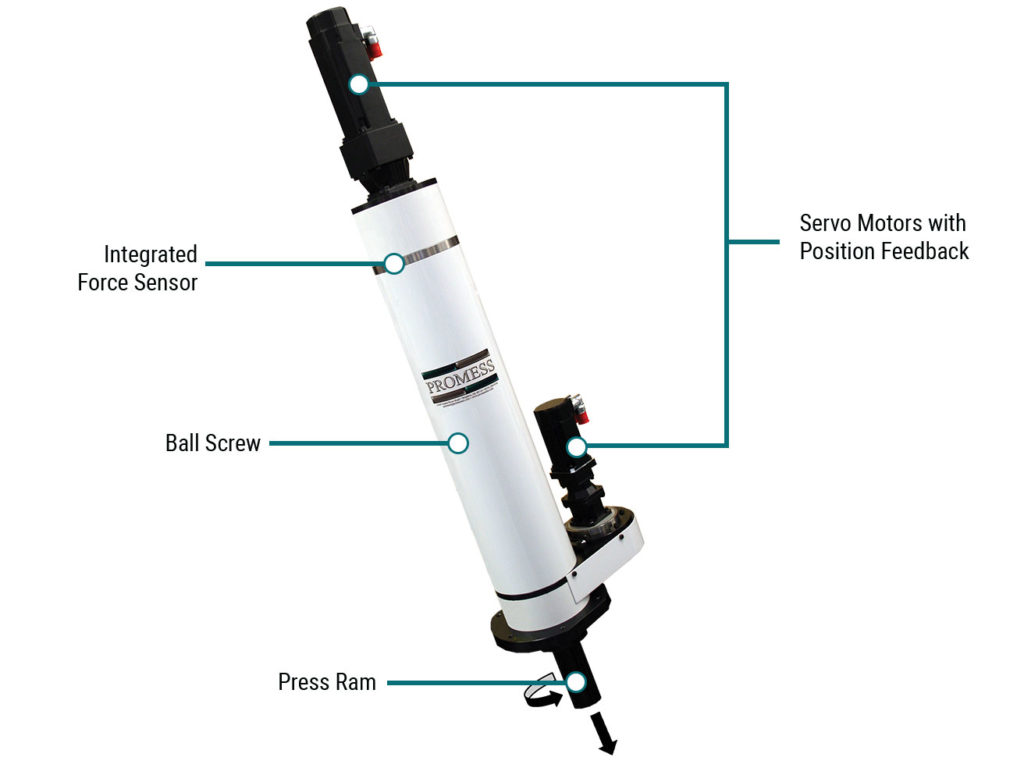

- Press ram extends, retracts & rotates

What is your application?

Talk to one of our expert engineers or learn more about proving your

application in our Process Development Center.

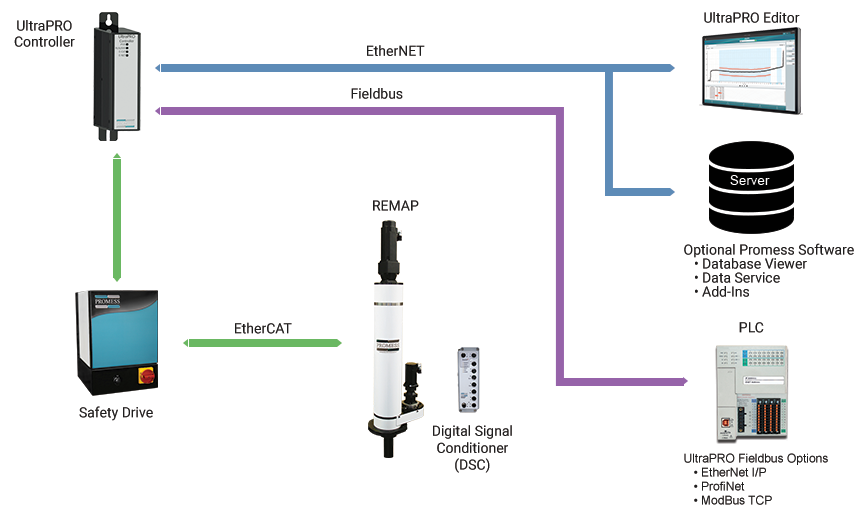

System Powered By Promess Software

Promess powerful system software solution offers custom commands, flexible configurations, and adjustable features to address your specific needs.

Features of Promess Software

- Easy to Use

- Traceability

- Data History

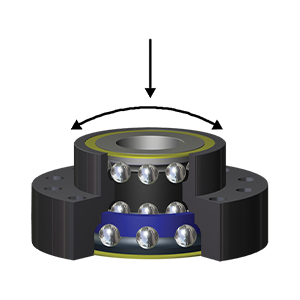

REMAP Mechanics

Complete System

System Includes

- Two fully programmable axes of motion

- Linear extend and retract

- Spindle rotation

- Integrated force transducers

- Integrated torque transducers

- Two servo motors

- Safety Drive Enclosure

- UltraPRO Controller

- Digital Signal Conditioner

- Motion control software

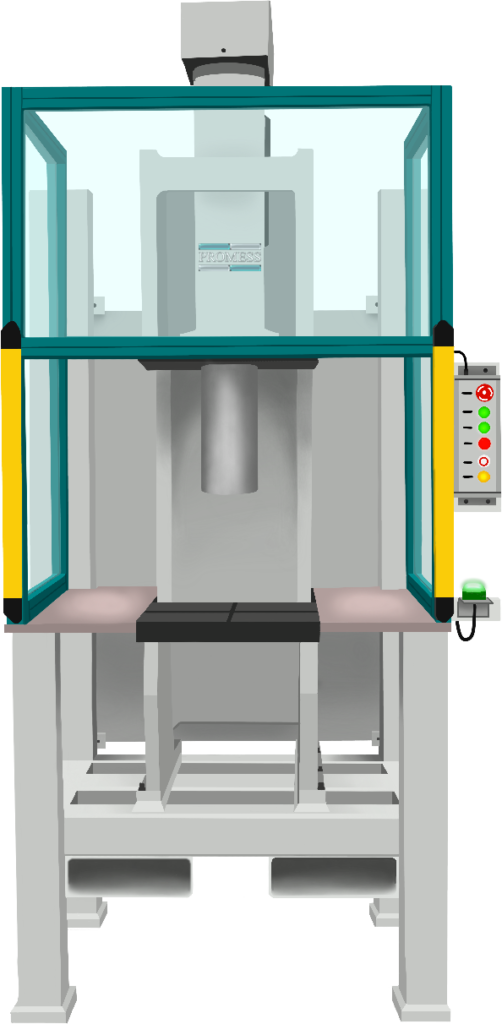

Looking for a More Tailored Solution?

Looking for a plug and play system that allows you to be up and running same day as delivery? Learn more about our Work Stations.

REMAP Sizing

Linear Axis

| Force (kN) | Stroke (mm) | Speed (mm/sec) |

|---|---|---|

| 1 | 100 | 200 |

| 5 | 200 | 200 |

| 12 | 400 | 200 |

| 20 | 400 | 200 |

| 30 | 400 | 175 |

| 40 | 400 | 200 |

| 60 | 400 | 150 |

Rotational Axis

| Torque (Nm) | Speed (RPM) |

|---|---|

| 20, 50, 100 | 250 |

| 20, 50, 100, 200 | 250 |

| 20, 50, 100, 200 | 250 |

| 20, 50, 100, 200 | 250 |

| 20, 50, 100, 200 | 250 |

| 20, 50, 100, 200 | 250 |

| 20, 50, 100, 200 | 250 |

Prove Out Your Process

The PDC is available to you for help verifying your process at no cost to you. Bring in or send in your parts and work with an engineer to find the technology best suited for your application.