In-Process Monitoring Systems | Torque Systems | Servo Presses

We are an industry leader in force and torque sensing applications, giving machines the ability to “feel” how a part or product is being made. Data is collected during these closed-loop operations, and manufacturers use that information to continually improve their processes.

Need Help Finding the Right Solution?

Not sure what solution is right for you, call us.

Challenges We Solve

✔ Minimize the Cost of Manufacturing and Automation

✔ Eliminate Part Quality and Warranty Issues

✔ Reduce Machine Downtime

✔ Shorten Assembly Cycle Times

✔ Never Worry about Safety or Ergonomics

Prove Out Your Process

The PDC is available to you for help verifying your process at no cost to you. Bring in or send in your parts and work with an engineer to find the technology best suited for your application.

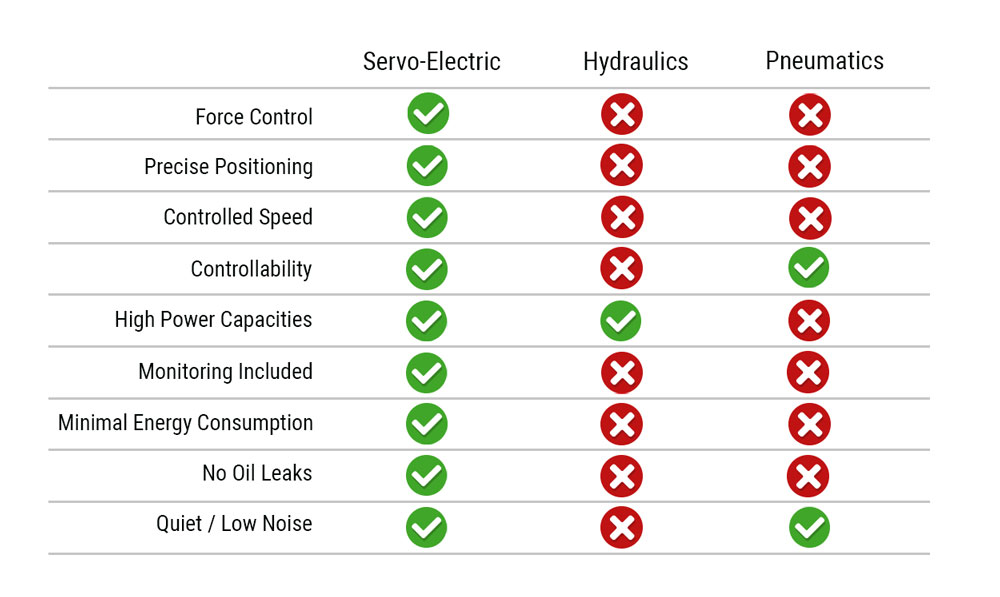

How We Compare to Other Technologies?

When looking for equipment to assemble your parts there are many options. Learn more about how do we compare to those technologies

WHAT OUR CUSTOMERS ARE SAYING

SMART MANUFACTURING

Knowledge Center

Events and Tradeshows

Promess Applications

Contact Promess

Watch Our Webinars

Read Our Blog

Request a Promess Greenbook

The Promess “Greenbook” is a compilation of product development, white papers, application reports, and customer references. If you are interested in receiving this comprehensive resource guide, please fill out the form and Promess will send one out.